This is the most common debate when approaching production modeling. We carry with us the habits and inertia of traditional 2D methods, which are often a burden. New methods require new approaches and require us to question each and every step we take. Excessive detail can mean the model is so cumbersome that it's inoperable. It can also mean a significant amount of modeling time and a significant loss of flexibility when it comes to modifications.

So, how detailed should it be? Well, the answer is simple: austerity should be our rule. We must simplify the geometries and only model those elements that require manufacturing or measurement. This may mean negotiating the deliverable with our client, but this negotiation should be based on a mutual interest in streamlining the modeling and exporting process. The only limitation is ensuring that information is not lost on the shop floor, nor does it cause confusion or inconvenience during manufacturing and assembly. This doesn't mean we should always model in a simplified manner; it simply means we should question whether it's necessary or not, and whether we can save ourselves unnecessary work.

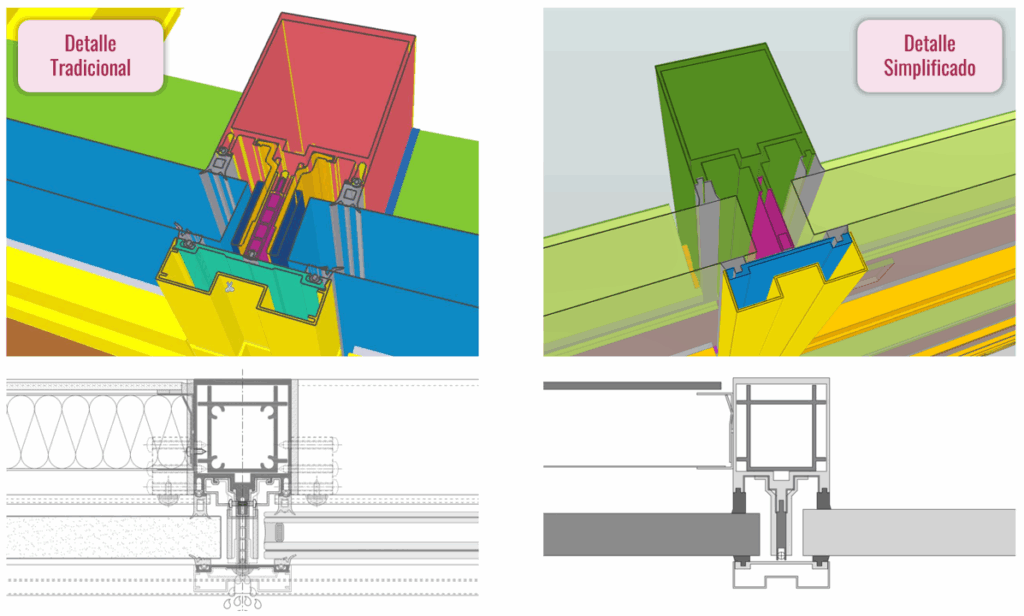

In the lightweight façade sector, this takes on enormous importance, since the elements that comprise it have traditionally been drawn in great detail, even accurately depicting the screw threads. This has always been a handicap for exactly the same reason. From the outset, a lot of time is invested in developing plans with a wealth of information and detail, with a high risk of modification after DF reviews. This is a perfect breeding ground for rework and delivery delays. This has always been a scourge for technical offices, which have seen a large number of wasted hours invested in drafting, and despite their efforts, they are always behind schedule. This means that the deliverable is neither functional nor compatible with the deadlines and margins currently operating in the sector.

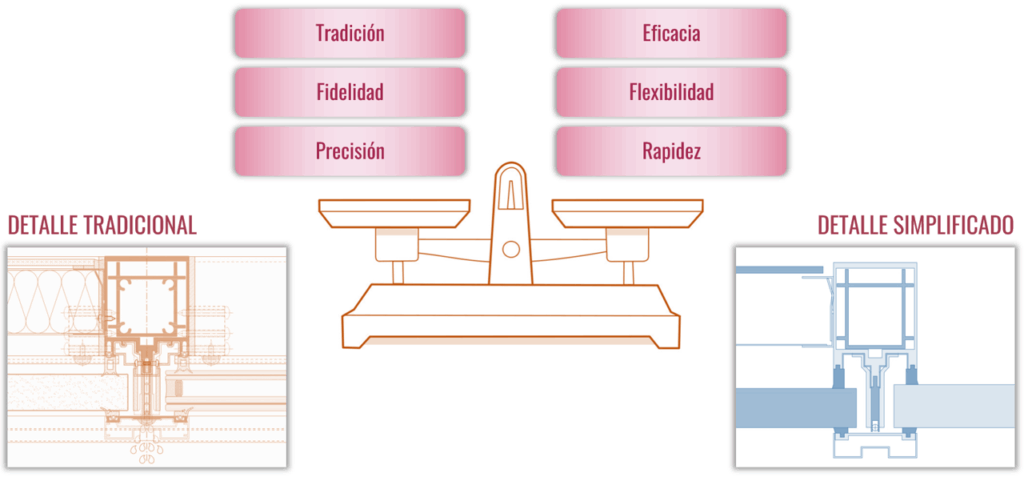

When weighing the pros and cons, on one side of the scale are tradition (work has always been done this way, and our client expects to receive the deliverable in the same way), fidelity (what is modeled corresponds 100% to reality), and precision (we model with exact knowledge of the shape and dimensions of each part). On the other side are efficiency (a correct ratio between effort and benefit or functionality), flexibility (it takes less time and fewer errors are made each time a modification is made), and speed (the time invested in obtaining the first results is reduced since it is easier to model).

What do you think?

What has been your experience in this regard?

Contact